Compact CLT production plant for Holzbau Driendl

Small and flexible plant for smaller productions or as a pilot plant.

The family business Holzbau Driendl, an ecological woodprocessing business with its own small sawmill in the Oberallgäu region, decided to expand its activities and invest in its own flexible CLT production plant, which perfectly complements its existing activities and also involves younger generations of the family business.

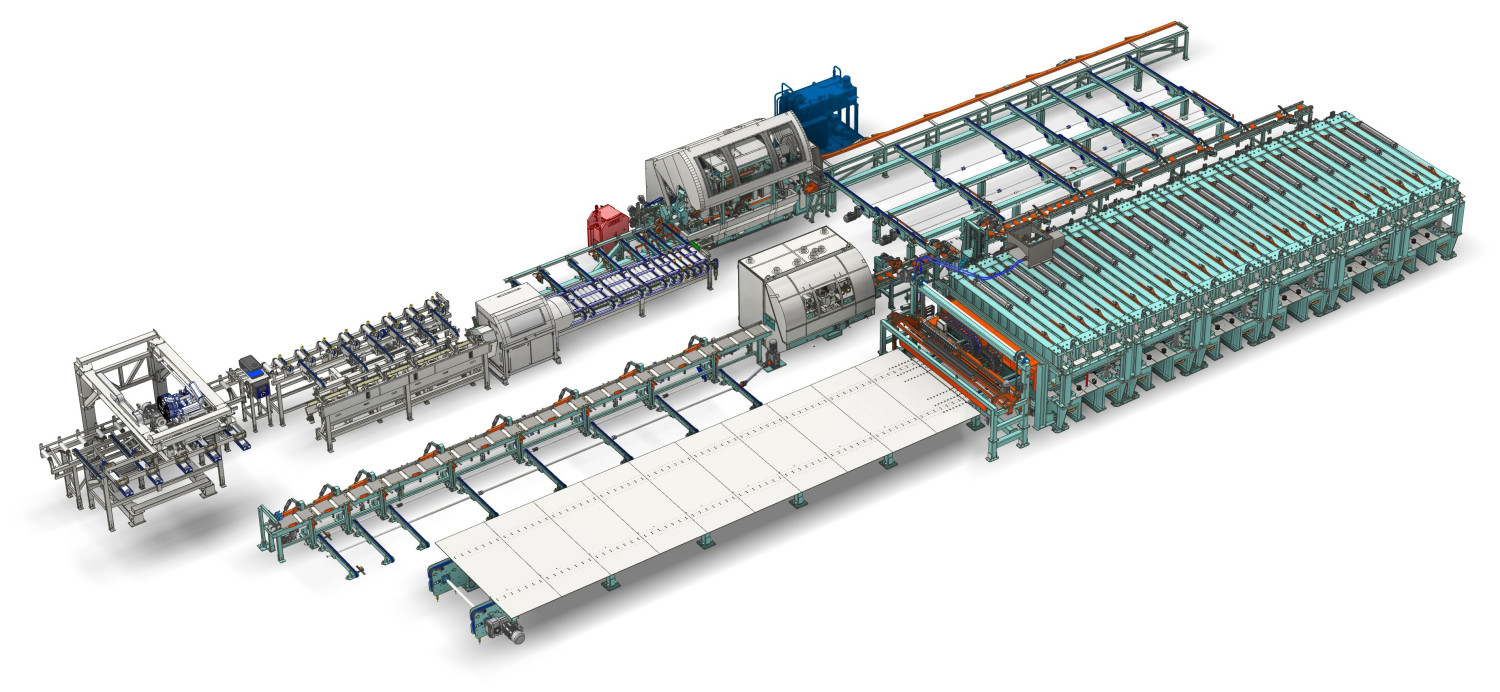

The compact plant was a challenge for the development team, both because of the very limited space availability and in terms of technical solutions that are economically adapted but still allow the desired capacity and flexibility while involving as few operators as possible. The plant consists of an automated finger-jointing line with manual marking before defect cutting and the new Ledinek BSP press for manual layup with automatic gluing function, which is located separately.

The press is equipped with both, side pressure and front pressure. Press closing and pressing is done by the operator by means of a control panel. The size o the CLT panels is limited to 14 m x 3.5 m x 0.36 m. A CNC processing centre is also installed in the same building in order to process finished CLT elements in a timely manner.

Company: Holzbau Driendl GmbH & CO. KG

Location: Wertach/ germany

Owner: Familie Driendl

Kind of wood: mainly spruce

Operators: 2+1

Production capacity: 5.000 m³ / Shift a year

Glue: 1K-PUR by JOWAT 10/10 (finger joint gluing) and 40/60 (surface gluing)

System consists of:

1. Automatic vacuum destacking of the raw material

2. Moisture measurement

3. Reject gate for whole boards

4. Manual marking station for wood defects

5. High-performance cross-cut saw for defect cutting MPC 400 FAST

6. Feeding of the finger jointing machine

7. EUROZINK Compact 6-300 kN finger jointing machine up to 6 pieces / min

8. Curing storage for lamellas

9. Line-integrated cross-cut saw for cross lamellas

10. Feeding of the lamella planer PROFILES 220-4V

11. Automatic stacking system with integrated roller conveyor and cross chains for single-row packages

12. Layup table for manual panel assembly

13. Stationary LEDINEK surface gluing with PUR (1-component polyurethane adhesive)

14. XE-PRESS 14 cross laminated timber press with high specific pressure up to 0.8 N/mm²

15. Raw pressed CLT panels

16. Freshly CNC machined panels from a Hundegger PBA

Facts

- Up to 14 m x 3.6 m x 0.36 m panel size

- Production capacity up to 5,000 m³/year

- Operators 2+1

- PUR adhesive for higher capacity

- High flexibility of the production process