Lines

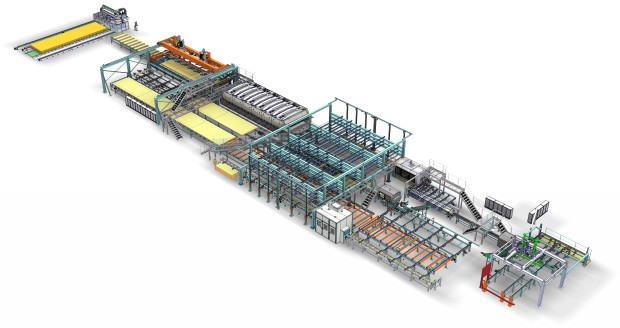

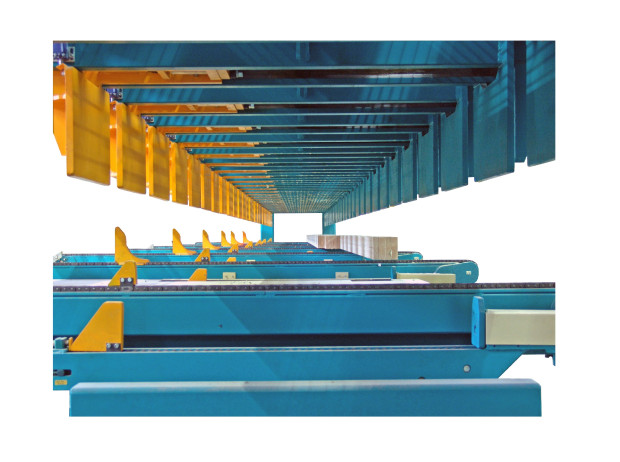

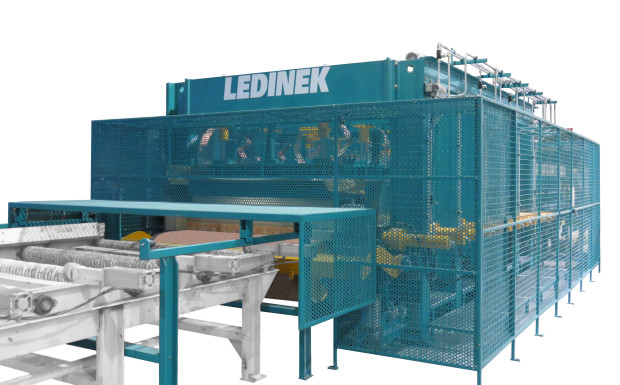

CLT lines

Complete CLT production lines for cross laminated timber panels. CLT production capacitys from 5.000 m³ per shift per year up to over 100.000 m³. Turn-key solutions in different levels of automation. Our wide range of products comprising planers, finger jointing machines and presses enables us to offer custom made solutions for different CLT production volumes and processing steps. We take care of the entire package.

CLT production line in LatviaCLT production line in JapanCLT production line in AustraliaCLT production line in FranceCLT production line in NorwayCLT production line in SwedenCLT production line in UkraineCLT production line Binder in GermanyCLT production line in CanadaCLT production line in RussiaCLT production line Ante in GermanyStandard cross laminated timber plant in PortugalCLT production line in SwedenCLT production for Mayer Melnhof in LeobenCLT / GLT production in UruguayCLT production line at MosserCLT production line at Driendl

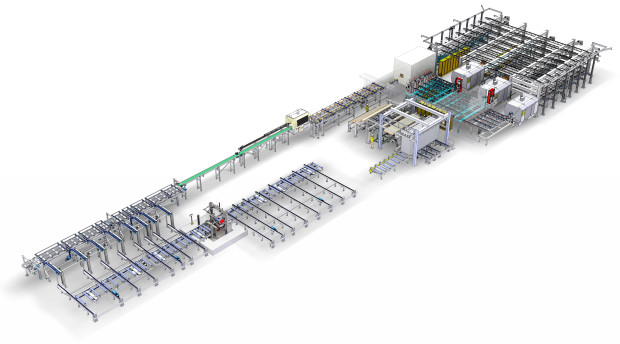

Glulam lines

Excellent pressing solutions for straight and curved glulam beams. Highly adaptable production lines for commissioned goods with solutions emphasized on short pressing time or lines with big batch volume. Everything from a planer, to a press and to handling equipment, from one supplier.

GLT production lineGLT production line in SwedenGLT production line in LithuaniaGLT production line in AustriaGLT production line in SloveniaGLT production line in Poland

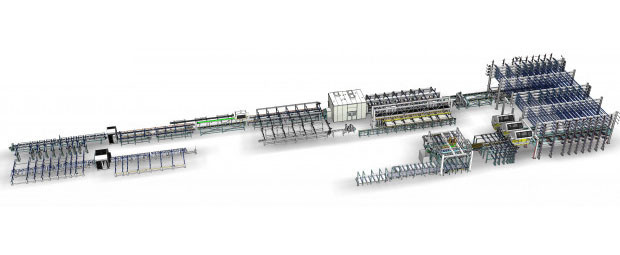

Solid finger jointed timber lines

Innovative and individual, high performance single piece finger jointing solutions with superb utilization factor and workpiece yield for large and medium sized enterprises. Finger jointing lines for solid constructional timber, laminations for glued engineered products or for boards.

Machines

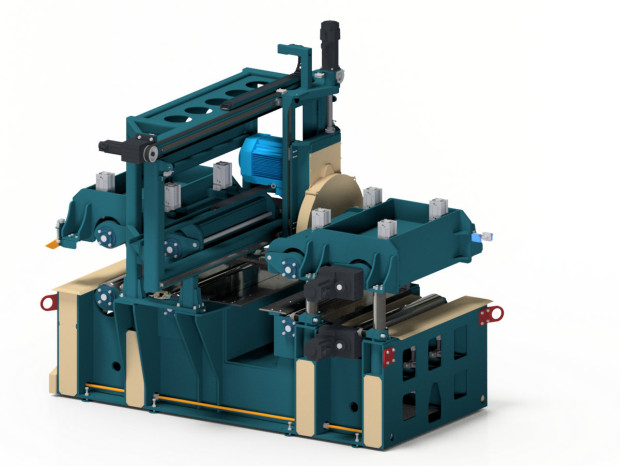

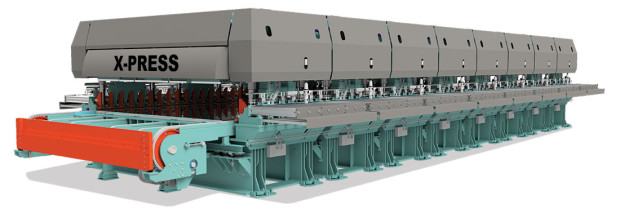

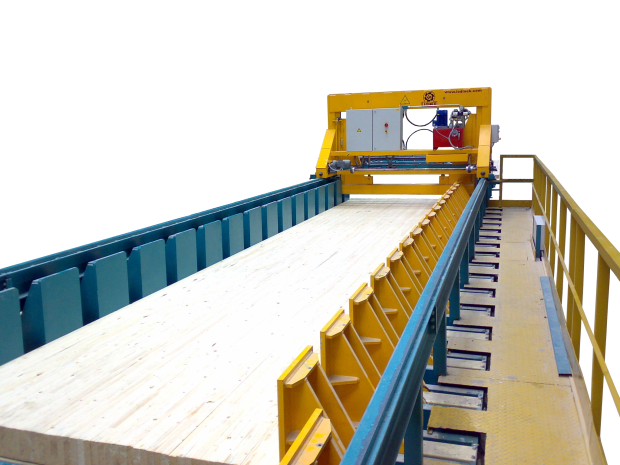

X-Press

Press for cross laminated timber panels. Pressing force achieved with pressurized air. No hydraulics – no leaks. Strongest specific pressure 0,8 N/mm². Side and face pressure. Designed for fast glues. CLT Press. XPRESS

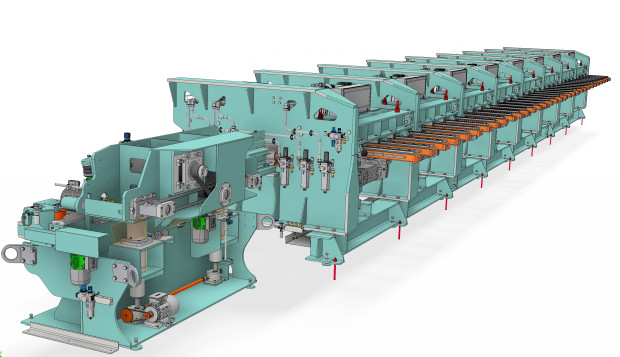

XM-Press

The XM-PRESS is a CLT press to produce a unique (longitudinally orientated) format of cross laminated timber panels. The XM-Press is designed modular and can be produced in 2m steps (6m – 20m).

Z-Press

Edge gluing press with hot-melt for fast assembly bonding of solid wood laminations.

Multiple widths or continuous single-layer panels are produced from edge glued laminations.

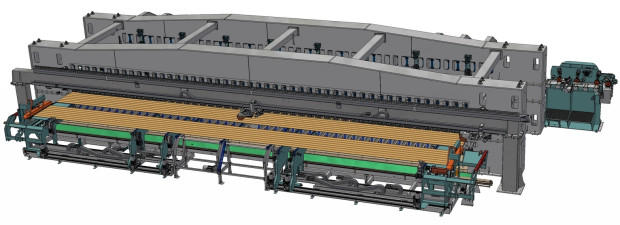

Unipress

Heavy automatic through-feed edge gluing press for the production of solid wood edge glued panels and complete CLT panel layers.

Rotopress

Rotary press for commissioning goods. Straight glulam. Stepped batches. Four pressing beds. Motorized clamping. Short loading and curing time.

Maxipress

Top mounted press for commissioning goods. Straight glulam, DUO and TRIO beams. Stepped batches. Small footprint. Motorized clamping. Short loading and curing time.

Flexipress

Horizontal press for straight glulam. Large production volume. Stepped batches. Hydraulic clamping. Modular design.

Hyperpress

Curved beam press for biggest dimensions. Curved and straight beams. Easy positionable pillars. Rapid unlocking system. Strong hydraulic clamping. Longest lengths.

Polypress

Automatic curved beam press. For single curved glulam beams. Automatic loading and unloading. CNC controlled positioning. Fully programmable pressing. Straight and curved press bed.

HF-Press

High frequency glulam press. Small footprint. High production volume. Very fast curing. Strong hydraulic pressure.

HTBS

Horizontal band resaw. Excellent cut quality. For splitting of glulam. Strong and fast. Integration in automated lines.

LKS

Cross-cut saw for large cross sections. Exact length cut of layers. For commissioning goods. Up to 300 mm cutting height – different lengths. Servo positioning. Under-table or over-table versions.